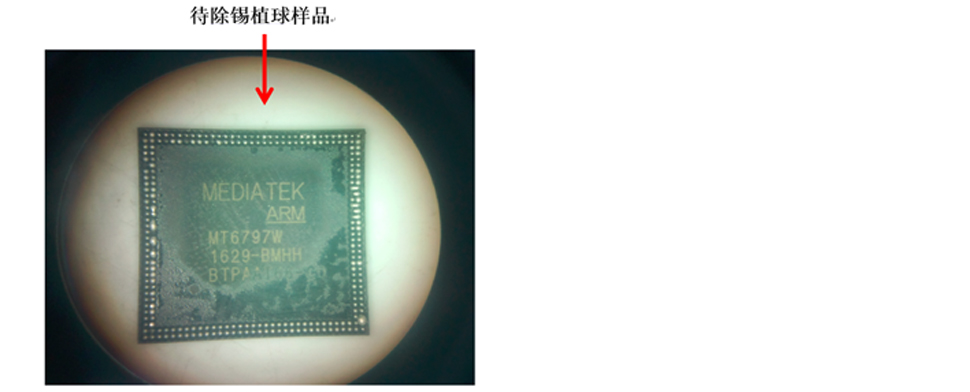

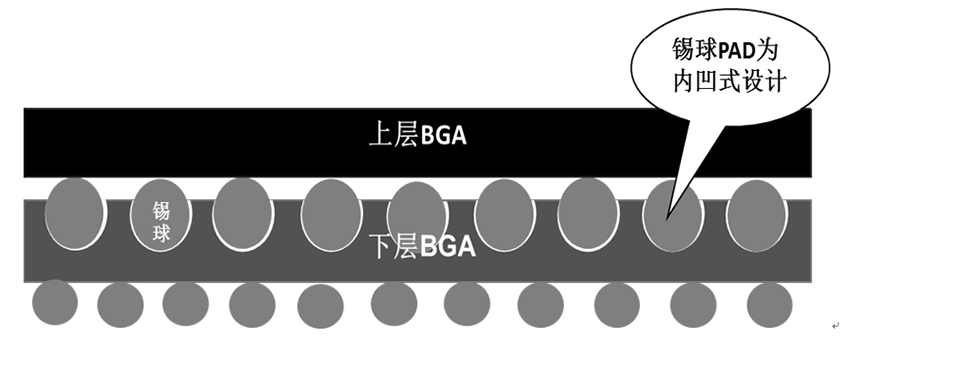

Due to its high cost performance, MTK chips are widely used in many mobile phone designs. In the case of manufacturing or bad analysis, it is necessary to rework and re-weld it. However, due to the use of pit-ball soldering in the chip design, manual tin-removing is difficult and the success rate is extremely low. A large number of products are scrapped.

Below we will introduce the actual case, through our company's overall solution to achieve its repair and welding.

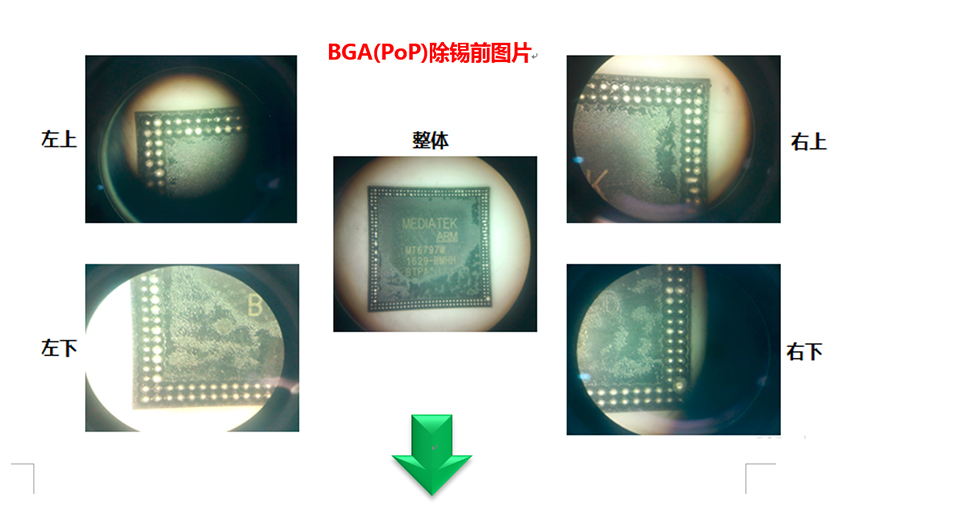

Because of the pitted ball, it is difficult to remove the tin by hand!

First, the verification criteria and requirements:

1. Purpose / Use:

The need to rework BGA products during the manufacturing of electronic components, such as:

1.1 BGA (POP) on the mobile phone, tablet, computer PCBA;

1.2 Re-use of tin/bulb ball for a single BGA chip;

1.3 Analysis of bad BGA, the cause of the need to be implanted and then welded or tested;

2. Requirements:

2.1 When the BGA is desoldered, the appearance and function of the BGA or PCBA cannot be damaged.

2.2 Non-contact safe tin removal is required when removing BGA from tin.

2.3 After the BGA is implanted, the BGA's ball path $Pitch needs to be the same as the original.

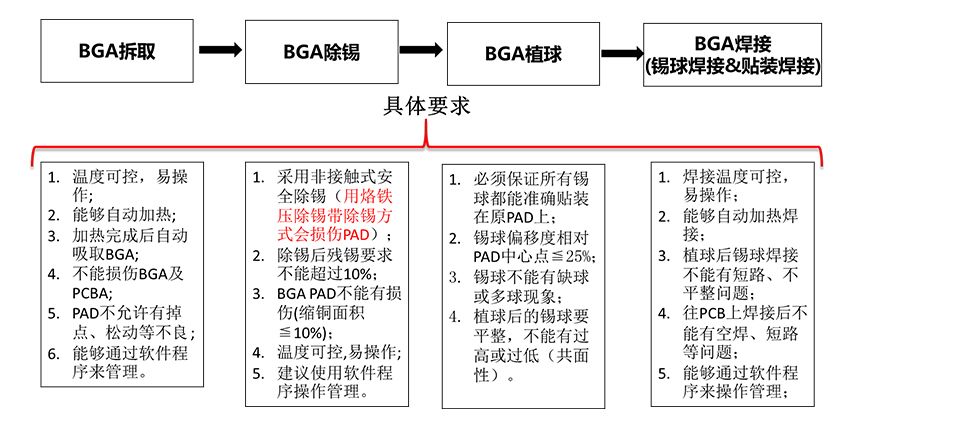

二、Verification standards and requirements - main application process descriptions and requirements:

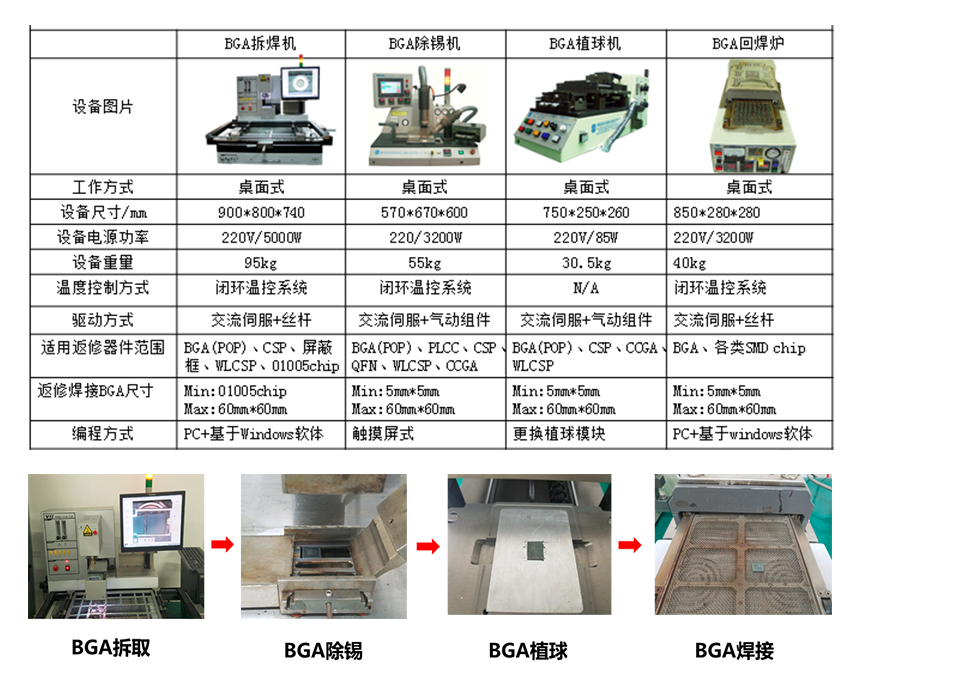

三、Verify BGA ball rework overall solution equipment information

四、Verification result icon

五、Quality reliability test results

For more information, please visit the URL:http//: www.vttech.cnOr call: +86-769-23226000 consultation, thank you!

For more information, please visit the URL:http//: www.vttech.cnOr call: +86-769-23226000 consultation, thank you!

中文网站

中文网站 English

English